Slim, strong, home-made shelves are simple to make

By Bob Hulme

No matter how much storage space you have, there is always a need for more. One solution is to make better use of existing cupboards and wardrobes. In my own house, the third bedroom is used as an office, so the built-in wardrobe was an obvious target for conversion into a storage place for files and computer supplies.

I had already tackled one shelving upgrade. We have a hallway cupboard used for many things that don’t have a place anywhere else, including toys for the grandchildren when they visit. The space was not used well. My solution was homemade shelving using frames of steel with plywood shelves.

For this cupboard, we had to allow for a basket of toys and chillibin on the floor level and picnic items and other bits and pieces on other levels. Once the shelves were installed, better use of space meant more room became available. One of Murphy’s Laws soon came into play, and other items found their way into the open spaces, making good use of the variety of shelving.

Why not all timber?

The steel and plywood shelves are self-supporting when screwed together and have plenty of strength, too. Why don’t I make them all out of wood? Using steel means less space is taken up by the structure, so that there is more storage space. I also enjoy working with a variety of materials—and have you seen the price of timber lately?

I favour plywood over MDF board because it is less prone to bowing. I have bought some very cheap storage cabinets in the past, only to find after a short space of time that anything heavier than a matchbox on the shelves means they soon droop alarmingly in the middle.

Planning

Before cutting any material, it is essential to plan what is going to go where and establish the shelf spacing. There are only two basic rules that apply:

- The space under the bottom shelf should be generous to allow for cartons of things to be put there. Heavy and bulky items are best stored on the floor.

- The space above the top shelf should also be generous, as a narrow space will be difficult to access and see into. Use this space for the least frequently required items.

For a home office storage area, measure file storage boxes, lever arch files, DVD boxes etc to establish various shelf spacings. Position the narrow shelf spacing at eye level.

Basic sketch

Once the shelf positions are established, do a simple sketch showing heights, widths and construction layout. This will make it much easier to tackle the job in stages and as spare time allows. There is nothing worse than coming back to a project after a week has passed, then wasting time working out where you were up to and what you had already decided.

I designed two end frames and a free-standing middle frame, with the angle iron supports for the shelves across the frames. The frames are held in place once the ply shelves are screwed on through the angle iron at both ends and in the middle.

Materials

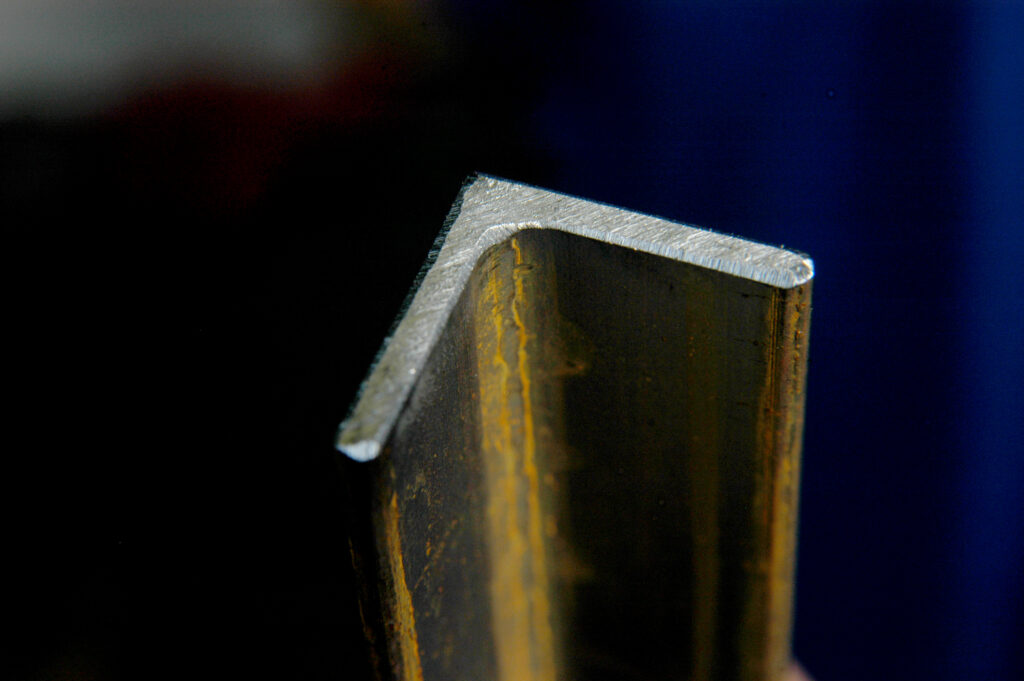

For the uprights, I used 19 x 19 mm square tubing with 2.0 mm wall thickness and 20 x 20 x 3 mm angle iron for the cross-members. The shelves are made from 15 mm-thick plywood. This can be the grade that is flawed on one side and filled and sanded on the other, so it has a good side and a rough side. Using the good side up allows items to slide easily on the shelf.

There is no need to use marine-grade ply. That is only necessary for outdoors or potentially wet areas. I did not apply any type of finish to my ply shelves but you could use an oil finish or polyurethane to give a more refined look.

Frames

From your sketch, make a cutting list. Cut the angle and square tube pieces as accurately as you can, as this will make squaring up and welding easier. At this stage, drill screw holes in the pieces of angle for the screws which are used to secure the ply shelves from underneath and hold the whole shelf together. The 5 mm diameter holes will suit both 8g and 10g screws. If you want to use countersunk screws, then countersink the holes. File off any sharp edges.

The trick to welding up the frames is getting them square. Lay one upright on a level floor and clamp the angle support for the top shelf to the top of it. (The upright frames do not have to extend any higher than the top angle cross members).

Square

Use a rafter square to ensure the two pieces are as square as possible. Just tack-weld the pieces together. This allows you to make small adjustments with just light hammering to make the frame square before final, full welding. Do the same for another square upright, but this time position the angle cross-member where the lowest shelf will be.

These two L-shaped parts can then be placed together on a flat surface to be tack-welded together and adjusted for squareness. Use the rafter square again and check by measuring across the diagonals which should measure the same. If you have cut the pieces accurately to begin with, this works well.

Welding

There are a number of ways you can weld up the frames. What you use will obviously depend on what equipment you have. MIG welding is quick and easy once suitable machine settings have been established. TIG welding will result in a very neat job. Stick arc welding is possible with small diameter rods(2.0 or 2.5 mm).

I used an oxy-acetylene gas torch because it can produce a nice-looking weld, and I enjoy this. My torch is a Henrob with a distinctive pistol-grip style. It wasn’t cheap, but I just had to have one after seeing a demonstration of it at a car show at Claudelands, Hamilton, some years ago. Unfortunately, there does not seem to be a local agent any more, and with prices of MIG and TIG welders coming down so much, I expect the market has shrunk significantly.

Assembly

The steel frames need some sort of coating to prevent rusting. I got mine zinc electroplated, as this is an all-over protection that is quite resistant to physical knocks. Electroplating compares well with the cost of painting, and there is black zinc plating available if you prefer. You can, of course, paint them. Use a good primer under the top coat(s).

Plastic knock-in ends are available for protecting the base of the square tubing. These can be used to lessen marks on the floor or carpet. I did not use these, as I figured the shelves are in cupboards and basically out of sight, but you might like to consider them.

Plywood shelves should be cut to the full width of the frames and half the overall length. (They will not be able to be fitted together in place if full length). The corners will need to be checked out to clear the square tube uprights—except for the very top shelf.

Fit the top shelf first, then progress downwards. This means that you will always have room to get at the screws.

So there you go. You will have more storage available, your life will feel more organised and you didn’t have to increase the mortgage to build onto the house.

THE DHC 2000 WELDING TORCH

Originally invented by Ed Dillon and known as the Dillon welding torch. Henrob Corporation later acquired the rights to manufacture it. Then, in April 2003, Cobra Torches Inc. purchased the rights, and that is how it has now become known as DHC 2000.

Superior performance is claimed through a different gas flow and frame shape. Materials with a degree of contamination can be welded without fluxes. I just find it a delight to use. One of the differences between this torch and the more usual oxy-acetylene ones is that it is used at a steeper angle to the workpiece (closer to vertical). Around 20 degrees off vertical is recommended. For proper operation, it is important to keep both oxygen and acetylene pressures to 4 psi. For more information, go to www.cobratorches.com.

PLYWOOD

The use of wooden panels made from layers of veneer glued together has been around since Egyptian times.

Plywood gets its strength from the alternating veneer layers in the grain direction at 90° to each other.

The veneers are scraped from the logs using a special lathe with a wide blade that peels off the delicate layer as the log rotates. In the 1800s, plywood was used for the wall panelling, chests, sewing machine cabinets, chairs, doors and even in the musical instrument industry for pianos and stringed instruments such as violins.

In the 1920s, the technology of synthetic resins as adhesives brought about a huge improvement in plywood quality and increased its uses. Wars seem to accelerate the application of new materials; during World War II plywood was used for boats and certain aircraft, most famously the Mosquito fighter bomber known as the “wooden wonder.” Today, plywood is a popular material for homebuilt aircraft.

Plywood now has several grades from the highest quality, appearance-grade veneer suitable for high finish to the lowest non-appearance grade with open defects and not suitable for painting. Home building regulations recognise the strength and durability of plywood by its acceptance for wall bracing and as flooring for “wet” areas. Where would Popular Mechanics be without plywood? Nearly every issue I have seen has a project made from this tough material.