All woodworkers need several squares, but not all squares are created equal

By David Blackwell

Photographs: David Blackwell

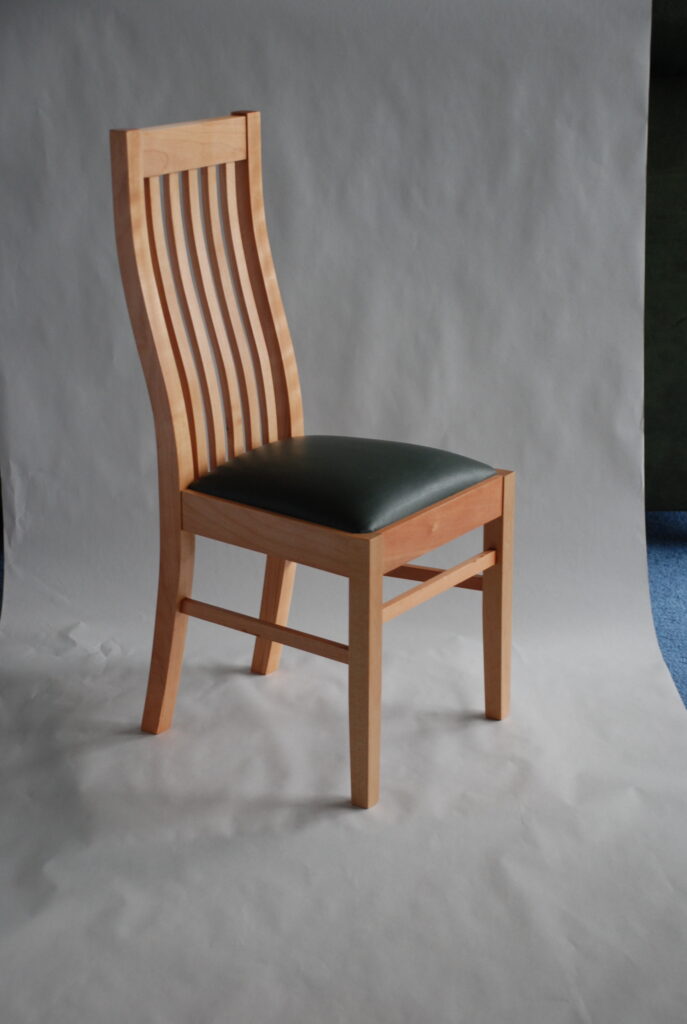

We need a range of squares to use for the many different situations we encounter in the workshop. For instance, we need a square to set up our machines – it is vital that your saw bench cuts square when you want it to. The blade obviously needs to be at right angles to the table, and the sliding table or sledge needs to be square. The same for your planer.

The fence should be set square, and you should regularly check that it remains square. Imagine the consequences of spending considerable time cutting mortise and tenon joints for fine furniture only to find they fit poorly due to the machined timber not being square. Errors also tend to compound over a project.

Tools for life

The most important point is that we must know that whichever square we use, it is sufficiently accurate for the purpose we intend to use it for. Generally speaking the type of squares available at the big box stores are made for the carpentry profession and the DIY market. These squares obviously fit the purpose as in most cases reasonably accurate is good enough.

In my workshop I have several precision engineer’s quality squares of varying sizes, and a number of other squares. My engineer’s squares are Moore & Wright and I still keep them in the original cardboard boxes even though I purchased them more than 50 years ago. Sadly Moore & Wright, an English toolmaking company, no longer exist.

I have two sets of combination squares, a Mitutoyo brand which is still very accurate and in excellent condition, even though I purchased it in the late 1960s, and a Chesterman brand which I inherited from my father. This, I estimate, is 60-70 years old, probably purchased in the early to mid 1950s. It is still accurate enough for most things I do, probably accurate to less than 0.001 of an inch over 8-10 inches. As a generalisation, most combination squares available in hardware stores are made for the carpentry trade. I have numerous other squares that I have acquired from relatives’ estates over the years but I would never use them except for when I was welding up a trailer or something similar.

Beauty can be skin deep

Recently, an acquaintance, who is an excellent model-making engineer, gave me a square that had belonged to his father. It has a wooden butt with brass and is in beautiful condition, but it is not really square for my type of woodworking. Even the blade tapers by several thou and the wooden butt will move with the changes in humidity. I will not use this square but it sits in pride of place in my display cabinet.

From time to time each square needs to be checked against something that you know is accurate. I tend to use my 12-inch Moore & Wright square as it is the square that is still in brilliant condition and I know I can trust that it is square. I do not have a surface plate but I use my saw bench top as it is a ground surface finish that I know is flat.

Squaring aids

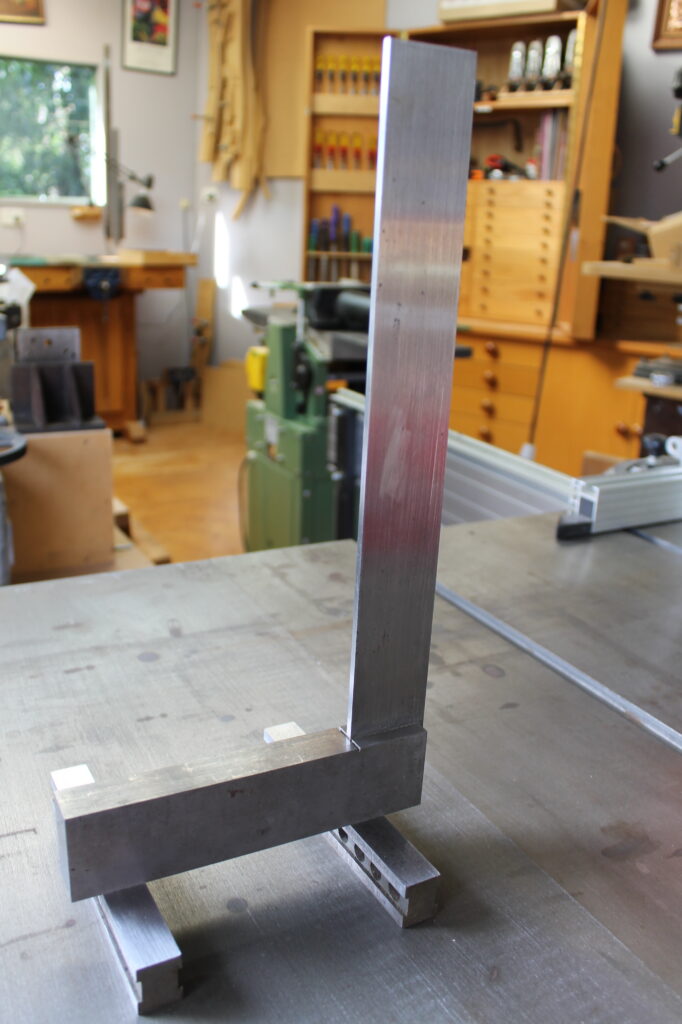

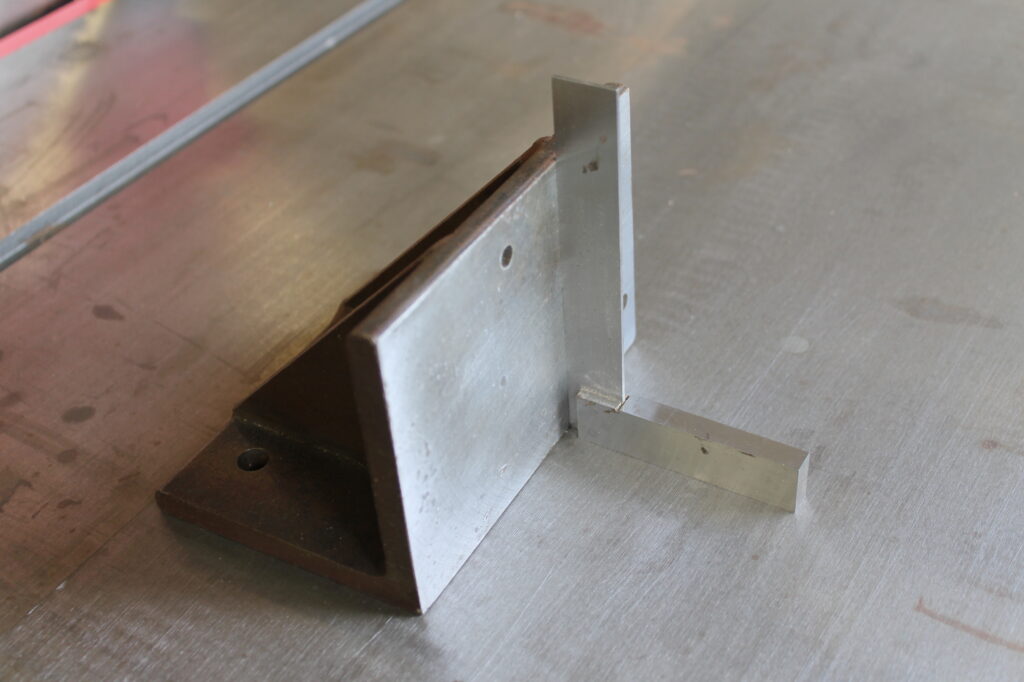

I also have two precision angle plates that I made about 50 years ago out of large angle iron. I used these on my old milling machine. These were surface ground and I find them excellent reference points when I want to check if one of my squares is still square.

I also have a couple of pairs of spacer blocks, originally made for use on my milling machine. These were case hardened and ground together so I know they are exactly the same height. They are handy when I need to lift a square a little for a particular job.

I use squares a great deal when I am making something in my workshop, and it is common for me to have several squares out on my workbench at any one time. They are certainly one tool I could not do without.

Storage and maintenance

Precision tools hate moisture, and so it is important for both the longevity of the tool and its continued accuracy that they are stored and maintained. My workshop is reasonably well insulated, excluding the roof, and while I keep it as dry as possible, unfortunately, from time to time, moisture does create some problems. I keep one of my historic sports cars in the workshop, and while I try never to put it away wet, sadly, at times I have no other option.

One way to help stop moisture is to lightly oil the tool (I use WD-40) and this can be sufficient for solving a short-term problem, but in fine woodworking the last thing you want on the piece you are making is any sort of oil residue. I tend to keep my tools totally oil free and as I use my tools very regularly I very quickly notice if any moisture issues arise.

Over the years I have made drawers for my tools and each time I try to make the draw sizes to take my precision tools, often in their original boxes.

Squares are a very special precision tool. I suggest you always buy the best quality you can afford and if you look after them they will last for generations.